-

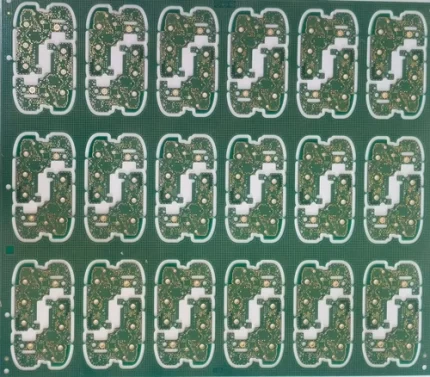

Hybrid Construction: Rigid-Flex PCBs integrate both rigid and flexible PCB materials into a single unit. This hybrid construction allows the board to bend or flex at designated areas while maintaining rigidity in other sections, offering versatility in design and functionality.

-

Flexible Areas: The flexible portions of the Rigid-Flex PCB enable it to conform to non-planar surfaces or fit into tight spaces within electronic devices. These flexible areas may include bendable sections, hinges, or connectors, depending on the specific application requirements.

-

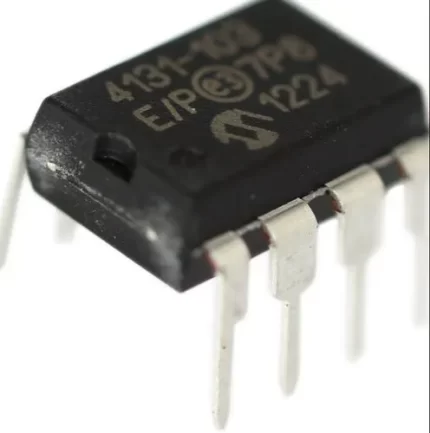

Rigid Areas: The rigid portions of the board provide structural support and stability to components mounted on the PCB. Rigid sections are typically used for mounting components that require a stable platform, such as integrated circuits (ICs), connectors, and mechanical support structures.

-

Space Saving: Rigid-Flex PCBs offer space-saving benefits compared to traditional rigid PCBs with separate flexible connectors or cables. By integrating both rigid and flexible elements into a single unit, Rigid-Flex PCBs reduce the need for additional connectors, cables, and assembly steps, thereby optimizing space and simplifying assembly processes.

-

High-Density Interconnects: Rigid-Flex PCBs support high-density interconnects, allowing for the integration of complex electronic systems into compact and lightweight designs. This feature is particularly advantageous in applications where size, weight, and reliability are critical factors, such as aerospace, medical devices, and consumer electronics.

-

Reliability: Rigid-Flex PCBs are engineered to meet stringent reliability standards, ensuring consistent performance under challenging operating conditions. Advanced design and manufacturing techniques, such as controlled impedance routing, thermal management, and signal integrity analysis, contribute to the reliability and durability of Rigid-Flex PCBs.

-

Customization: Rigid-Flex PCBs can be customized to meet specific application requirements, including size, shape, layer count, and material selection. This flexibility in design allows engineers to optimize the board layout for improved performance, functionality, and manufacturability.

-

Applications: Rigid-Flex PCBs find applications in a wide range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics. They are used in products such as smartphones, wearables, automotive infotainment systems, medical implants, and unmanned aerial vehicles (UAVs), among others.

Rigid Flex Pcb

$ 0

| Material | FR4 |

| PCB Grade | FR4 |

| Type | Multilayer |

| Copper Thickness | 18 , 35, 70, 105 , 210 micron |

| Layer | 1 Layer to 36 Layers |

| Line Width / Spacing | 3 Mil x 3 Mil |

0

People watching this product now!

Categories: Consumers Electronics, Lights & lighting

Description

Reviews (0)

Be the first to review “Rigid Flex Pcb” Cancel reply

Shipping & Delivery

Shipping and Delivery

At Naayatrade, we know how important it is to get your products to you quickly and efficiently. That’s why we offer a range of shipping and delivery options to suit your needs.

Choose from:

- Fast Air Freight: Ideal for urgent orders and smaller shipments.

- Cost-Effective Sea Freight: Perfect for larger quantities and longer lead times.

- Convenient Express Services: Door-to-door delivery for ultimate ease.

- Land Transportation: Reliable solutions for regional deliveries within specific areas.

Track Your Order:

Once your order ships, you’ll receive a tracking number to monitor its progress every step of the way.

Fast, Reliable, and Secure:

With Naayatrade you can be confident your products will arrive safely and on time.

More Offers

No more offers for this product!

Store Policies

Inquiries

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.